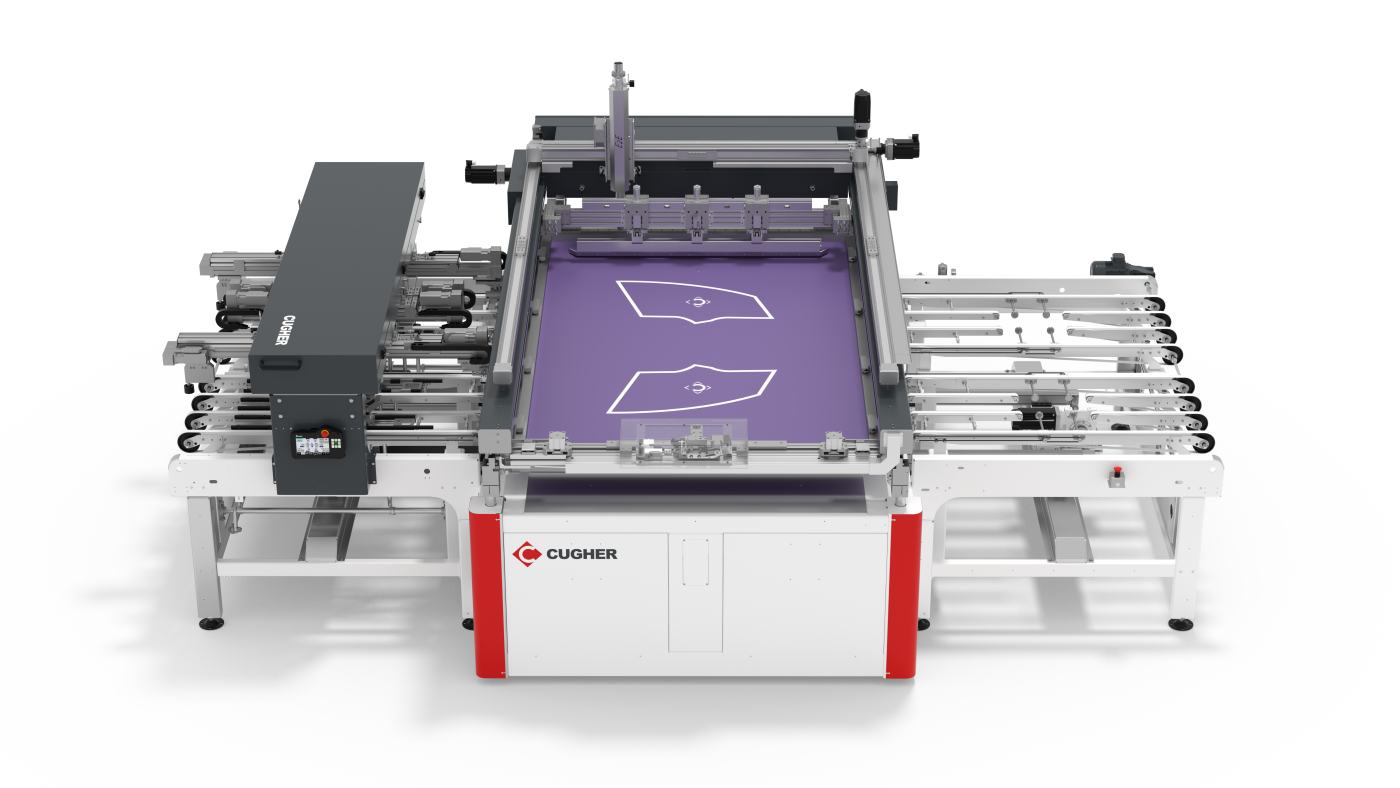

The Series G DLE (Double Lite Edition) has been engineered with the aim to have the maximum flexibility in a single printing line.

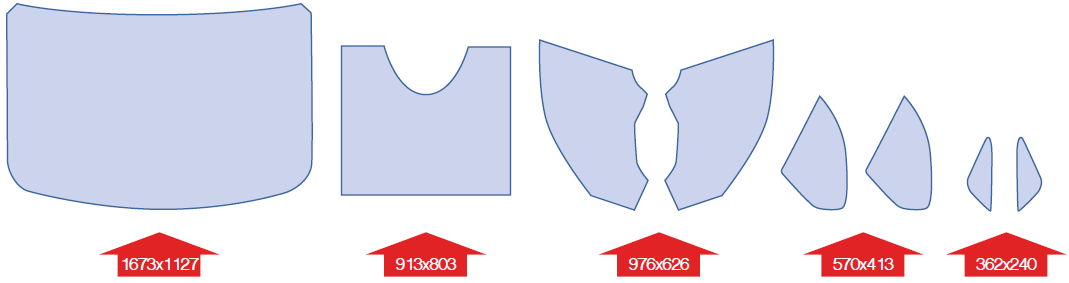

On one printing machine is possible to print two small glasses (sidelites or vents) or one single big glass (Backlite, Windshield or Sunroof).

| GB and DLE Series | G130x100-DLE | G200x130-DLE | G250x130-DLE | GB220x160 | |

|---|---|---|---|---|---|

| Glass max size (single LEL) | mm | 1300x1000 | 2000x1300 | 2500x1300 | 2200x1600 |

| Glass max size (double SEL) | mm | 550x1000 | 850x1250 | 1000x1250 | Paired glass |

| Glass min size (single LEL) | mm | 350x200 | 900x500 | 1000x500 | 950x450 |

| Glass min size (double SEL) | mm | 125x250 | 280x380 | 300x400 | Paired glass |

| Spessore Vetro | mm | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,2÷10 |

| Productivity*single glass | pz/h | 419 | 300 | 257 | 180 |

| Cycle time* single glass | s | 9 | 12 | 14 | 20 |

| Productivity* double glass | pz/h | 800 | 600 | 514 | na |

| Cycle time* double glass | s | 5 | 6 | 7 | na |

* max productivity and cycle time approximated, calculated on the maximum format and with print speed of 30m/min

Its outstanding centring system is composed by 18 axes that allow to perfectly centre even extremely shaped glasses.

The possibility to process on the same line two different type of glasses (i.e. Sidelites & Backlites) allows a great saving in terms of industrial space and cost optimization with a faster ROI.

The DLE is available in different sizes, from vents size up to windshields.

Automatic Centering System

- The system allows to insert into the recipe system the position of each pin.

- The operator can also define the pins’ closure sequence, allowing the centering of extremely shaped glasses.

- The precision of the centering systems can guarantee repeatability accuracy of 0,08mm.

- Glass dimension control, with alarm in case of out of range glass.

- Automatic print stroke setting.