Download

Applications 400°

– Annealing light alloys

– Preheating mold components

– Preheating filters

– Preheating extruded screws

– Preheating packs and dies

– Drying foundry core

– Treatment foundry core

– Treatment bushings

– Treatment carbon fabrics

Applications 600°

– Pyrolytic treatment in a reducing atmosphere

– Cleaning packages and dies

– Cleaning filters

– Cleaning extruded screws

– Treatment of titanium

– Tempering process

– Annealing process for softening

– Aging process

– Treatment springs

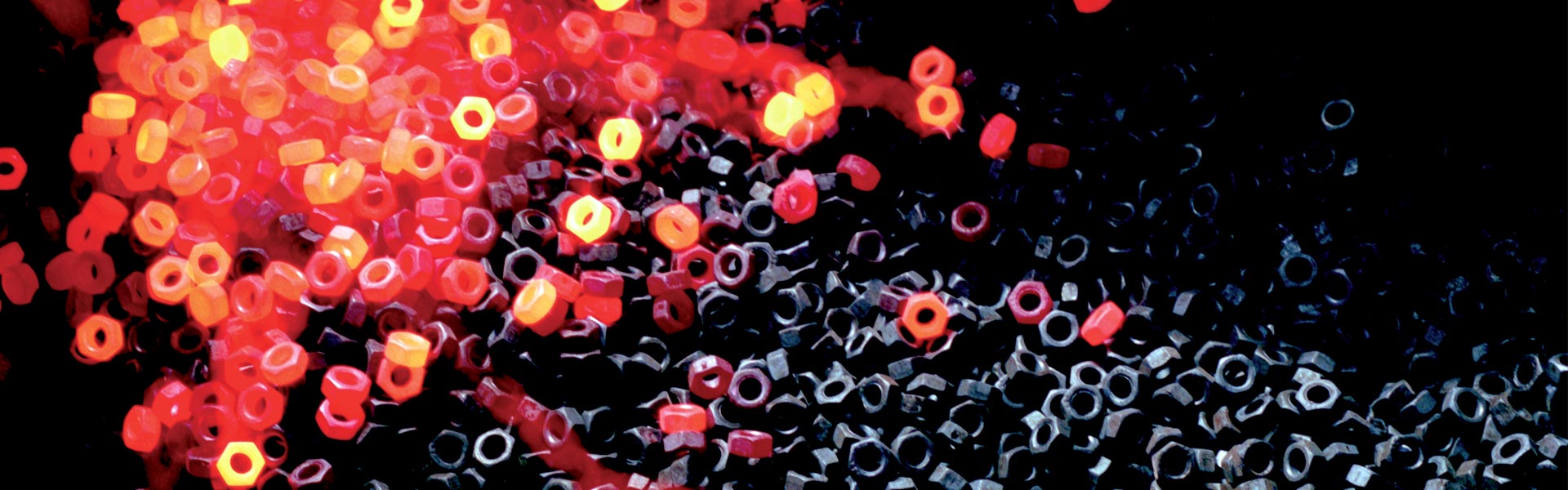

Applications 1000°

– Hardening metal parts and components dies

– Normalization treatment

– Cementation

– Carbonitriding

– Tempering

– Annealing

STANDARD FEATURES

Our innovative control technology provides for precise control as well as full documentation and remote monitoring of your processes. We improve the temperature uniformity, energy efficiency, reliability and durability of our systems with the goal of enhancing your competitive edge.

- Static or rotating batch ovens, depending on the material to be treated (PROCESS)

- Atmosphere management controlled in total safety (PROCESS)

- Completely automated temperature controls (PROCESS)

- Integrated thermal afterburner for exhaust gas cleaning (PROCESS)

- Robust construction, for heavy duty cycles (SAFETY)

- Over-temperature limiter with manual reset for thermal protection class 2 in accordance with EN 60519-2 (SAFETY)

- Furnace door locks after program start and cannot be opened again until the temperature has dropped below 180 °C at the process end (SAFETY)

- Air inlet openings for reliable air exchange (EFFICIENCY)

- Including floor insulation (EFFICIENCY)

- Dual shell furnace housing for low exterior temperatures (EFFICIENCY)

- Commissioning of the furnace with test temperature uniformity measurement for the purpose of process optimization (EFFICIENCY)

OPTION

- Loading-unloading customized system

- Vasca di spegnimento e sue specifiche attrezzature

- Racks, trays or customized loading devices

- A wide range of sample loading & handling accessories

- Controlled cooling system with frequency-controlled cooling fan

- Recording data, according to AMS2750-E (Nadcap) compliant applications