The high range of Cugher handling products allows transportation and stacking of glasses with any dimension and shape in all the directions inside production plant.

The material used and the assembly methods guarantee the maximum structural Safety and solidity and require a minimum maintenance activity.

Thanks to special design of Cipher systems, the handling happens using a minimum contact surface, offering at the same time the maximum grip.

The excellent integration and synchronization with all line components guarantee a very high productivity level.

The visual inspection systems, flat and vertical can be perfectly integrated inside the line, and allow to deeply check print quality without affecting production cycle.

BELT CONVEYOR

Belt conveyors are made by belts drawn by pulleys coupled to a shaft that move in the same direction as the glass flow. The structure is made by steel profiles powder painted to avoid any oxidation of the metal structures.

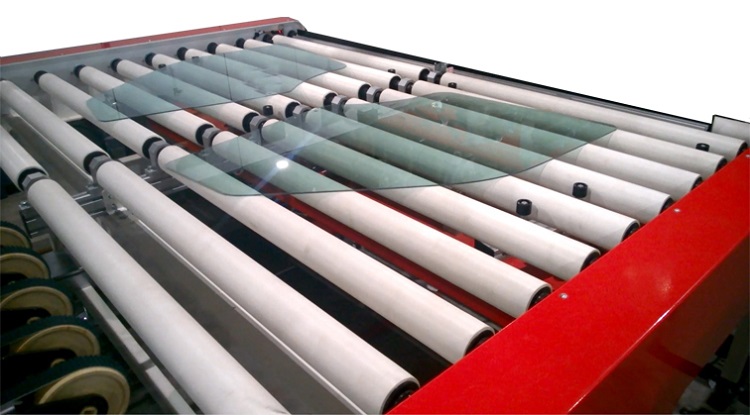

ROLLER CONVEYOR

Special conveyors with ground rollers powered by an alternating current motor. The design does not require welding and ensures extreme stability as well as easy maintenance.

TILTING BRIDGE

The conveyor has the ability to tilt, on request, a section of the conveyor, allowing the passage of personnel and/or material through the glass handling line.

LOADING/UNLOADING TILT CONVEYOR

The loading and unloading of the glass takes place thanks to a conveyor equipped with forks which, starting from a vertical position, are lowered until the glass is deposited on the transport rollers.

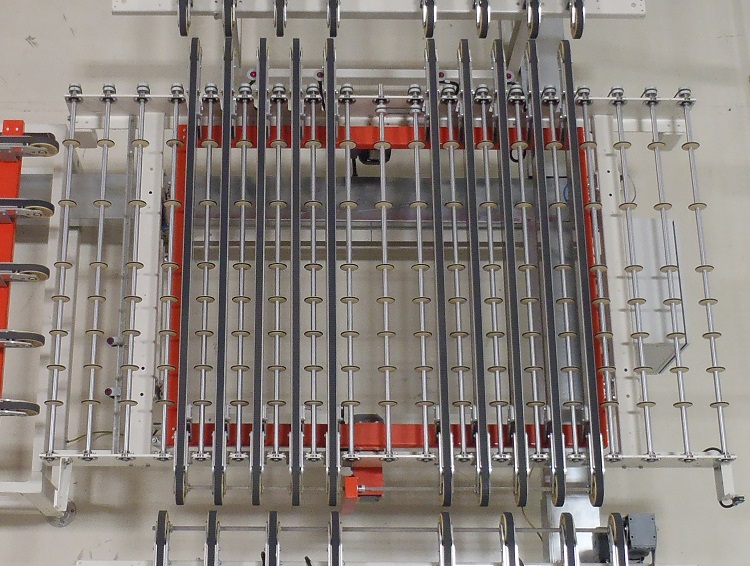

CORNER CONVEYOR

Combination of rollers and belts, where the belts move in the same direction of the glass flow and the rollers provide adequate support for the perpendicular transfer of glass.

STACKER

The stacker is designed to stack glasses, equipped with motors that activate the roller conveyor and with a chain for lifting the glass. When used as a conveyor, it is able to work following the speed of the line.

VERTICAL INSPECTION STATION

The vertical inspection station is used to check the quality of the printing without stopping the process. Between the rollers of the conveyor there is an arm-system which takes the glass bringing it in vertical position (70°).

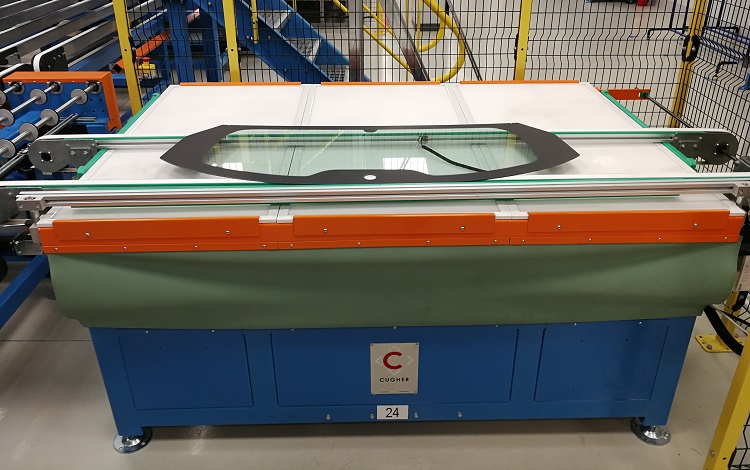

FLAT INSPECTION STATION

The inspection conveyor is equipped with a special box positioned under the belts to check the printing quality. The conveyor can be equipped with a handling system that brings it to a vertical position.

ROTATING TABLE

The belt conveyor allows the rotation of glass through a vacuum cups system. Rotation +90° or -90° is selected and confirmed by the operator control panel.

LIFT CONVEYOR

Belt conveyor that has the capability to lift the glass from a lower height to a higher one.

FLIPPING OVER

Double belt conveyor that rotates to flip over the glasses.

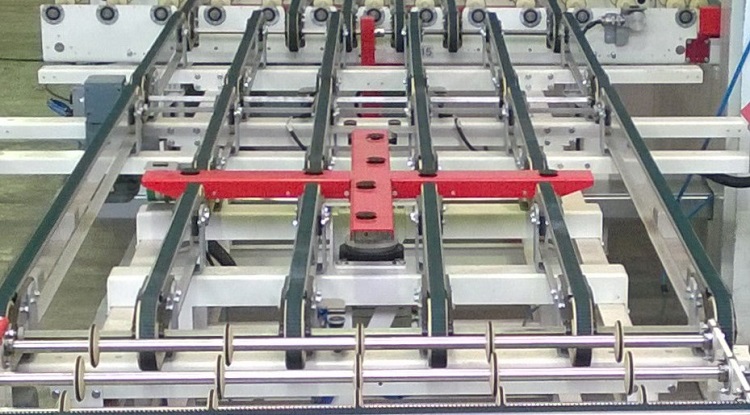

PAIRING STATION WITH ROTATION

Centering table with glass lifting system to pair the glasses. It allows to overturn the glass too.

WASHER BUFFER

Maximum five position’s stacker to empty the washer.

CULLET BIN

Removable cullet able to receive the discarded glasses, it can be lifted by forklifts on either side.

TURNING POT

Machinery to amalgamate the inks before the use.

SQUEEGEE SHARPENER

Machinery that allows to sharpen the squeegee.