Download

Applications 250°

– Aging plastics

– Softening plastics

– Drying powders and granules for molding

– Plasticizing frames (deep coating)

– Post curing seals and Viton O-ring

– Post curing seals and Silicone O -rings

– Post curing seals and EPDM O -rings

– Post curing seals and Nbr O -rings

– Vulcanization technical rubber profiles

– Aging plastics

– Softening plastics

STANDARD FEATURES

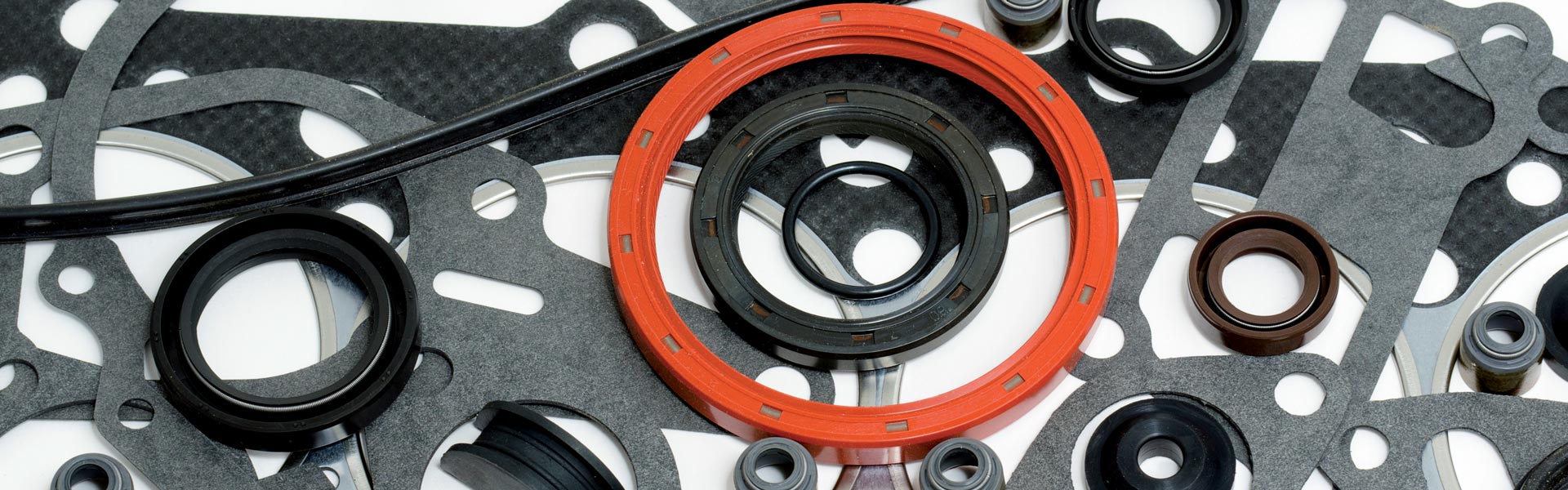

Grande versatilità di utilizzo abbinate ad una personalizzazione molto versatile: trattamenti di prodotti in resina, materiali compositi, post-curing di prodotti in gomma, trattamento di mole abrasive e polimerizzazione di vernici dielettriche. We can define with the customer the ventilation, able to ensure the best uniformity for each treatment: O-ring, sleeves, rubber tubes and customized gaskets. All units are fully factory tested, adjusted & certified, before the shipment.

- Temperature uniformity up to ∆T 3 °C according to DIN 17052-1 (PROCESS)

- Completely automated temperature controls (PROCESS)

- Air inlet openings for reliable air exchange, controlled automatically (PROCESS)

- Safety manage and elimination of gas and volatile residues, during the thermal cycle (PROCESS)

- Robust construction, for heavy duty cycles (SAFETY)

- Over-temperature limiter with manual reset for thermal protection class 2 in accordance with EN 60519-2 (SAFETY) Including floor insulation (EFFICIENCY)

- High-quality insulation for outer temperatures of < 20 °C above room temperature (EFFICIENCY)

- Commissioning of the furnace with test temperature uniformity measurement for the purpose of process optimization (EFFICIENCY)

OPTION

- Loading-unloading customized system.

- Racks, trays or customized loading devices.

- A wide range of sample loading & handling accessories controlled cooling system with frequency-controlled cooling fan.

- Design for clean room heat treatment processes recording data, according to AMS2750-E (Nadcap) compliant applications.