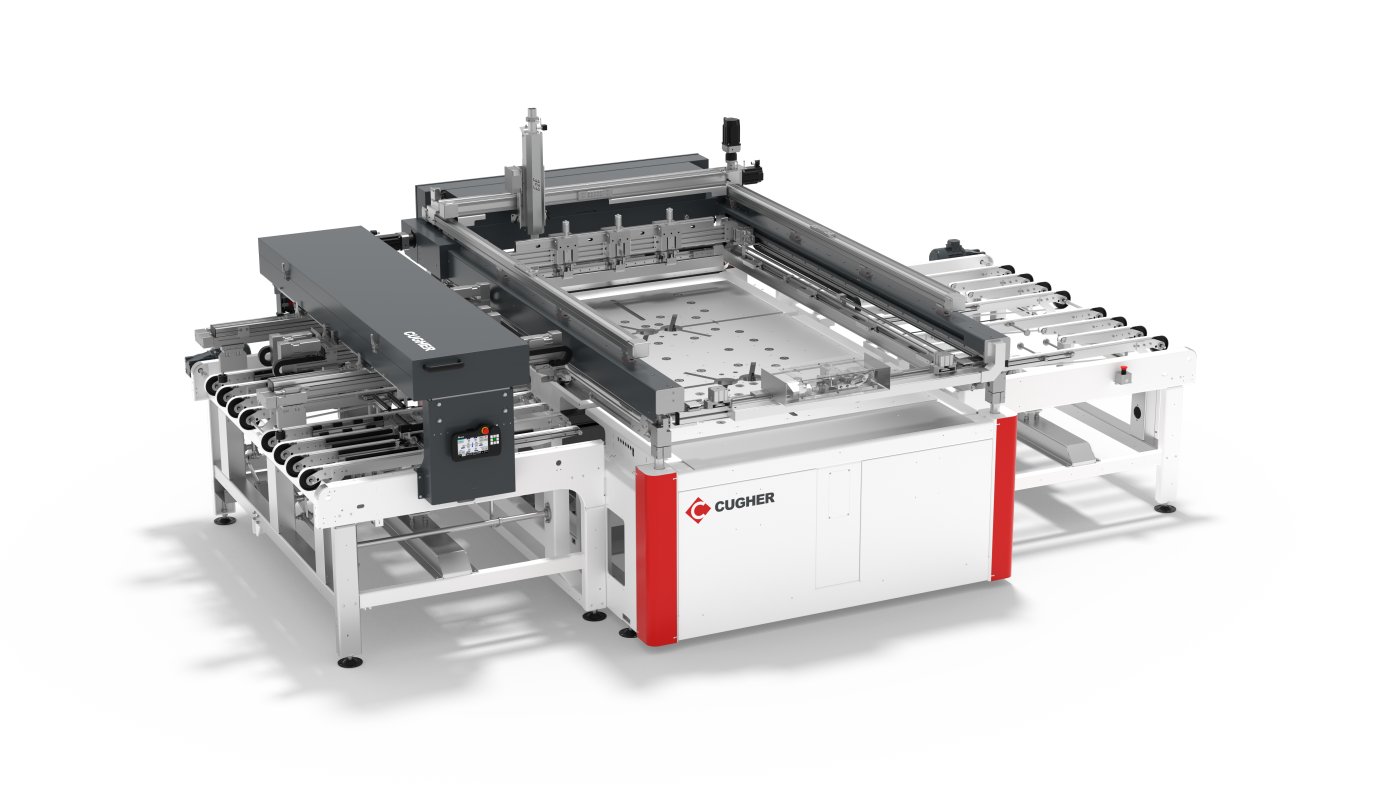

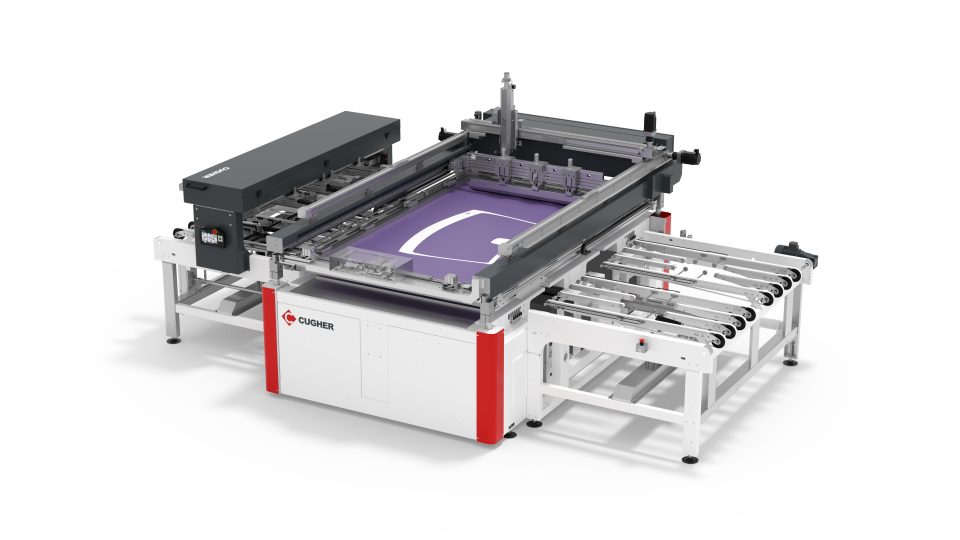

The G Series printing machines transport the glasses through a shuttle with two independent cross shaped holders and centring out of the printing table. This solution enables reaching the maximum speed of the printing process for glasses with small and medium dimensions. The system consists in one cross shaped holder with a vacuum cups system. The glass is collected by the walking beam while it is still in the centring device of the inlet conveyor; thanks to this operation it is possible to transport the glass with great accuracy. No further glass registrations are necessary before the printing process.

| G Series Long Edge Leading | 100x70 | 130x100 | 160x100 | 200x130 | 215x130 | 250x130 | 250x160 | |

|---|---|---|---|---|---|---|---|---|

| Glass max size | mm | 1000x700 | 1300x1000 | 1600x1000 | 2000x1300 | 2150x1300 | 2500x1300 | 2500x1600 |

| Glass min size | mm | 250x150 | 300x200 | 350x300 | 400x300 | 400x300 | 800x500 | 800x500 |

| Glass width | mm | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,4÷10 |

| Productivity* | pz/h | 480 | 419 | 360 | 300 | 286 | 267 | 257 |

| Cycle time* | s | 7.5 | 8.6 | 10 | 12 | 12.6 | 13.5 | 14 |

* max productivity and cycle time approximated, calculated on the maximum format and with print speed of 30m/min

| G Series Short Edge Leading | 70x100 | 100x130 | 100x170 | 130x200 | |

|---|---|---|---|---|---|

| Glass max size | mm | 700x1000 | 1000x1300 | 1000x1700 | 2000x1300 |

| Glass min size | mm | 150x250 | 200x300 | 300x400 | 400x300 |

| Glass width | mm | 1,4÷10 | 1,4÷10 | 1,4÷10 | 1,4÷10 |

| Productivity* | pz/h | 480 | 414 | 343 | 277 |

| Cycle time* | s | 8 | 9 | 11 | 13 |

* max productivity and cycle time approximated, calculated on the maximum format and with print speed of 30m/min

AUTOMATIC CENTERING SYSTEM

- The system allows to insert into the recipe system the position of each pin.

- The operator can also define the pins’ closing sequence, allowing the centering of extremely shaped glasses.

- The precision of the centering systems can guarantee repeatability accuracy of +/- 0,08 mm.

- Glass dimension control, with alarm in case of out of tolerance range glass.

- Automatic print stroke setting.

OUR MACHINE IS LIKE A DIGITAL CALIBER

Our system allows a perfect control of the height of the printing bridge, having a height position precision higher than 0,1 mm. The vertical movements of the printing bridge are controlled as a digital caliber, which has the “zero” represented by the printing table (perfectly flat, even surface) and the operator can set the desired height into the touch panel.

EASY CLEANING WITHOUT LOSING SCREEN REGISTER

Pull out of screen with pneumatic Screen Frame Locking System. The screen can be locked in position by means of pneumatic cylinders and it’s possible to use frames of different heights. Thanks to this feature, the operator doesn’t need to lock manually the frame, and the insertion and extraction of the screen results to be an extremely fast and easy operation.

SCREEN POSITIONING SYSTEM

Our machines can be equipped with three different systems, according to customers’ needs:

- Manual Calibers

- Motorized Calibers

- Fully Automated (see page Vision System)

- All settings are controlled from the operator side.

UNIFORM INK THICKNESS

Printing bridge with digital proportional valves.

Thanks to pneumatic calipers the squeegee and flood bar can be easily inserted/replaced.

NO MORE DROPS ON THE SCREEN

Anti-drip System: no more issue with light colours.