Double lites edition printing line

| YEAR | 2012 |

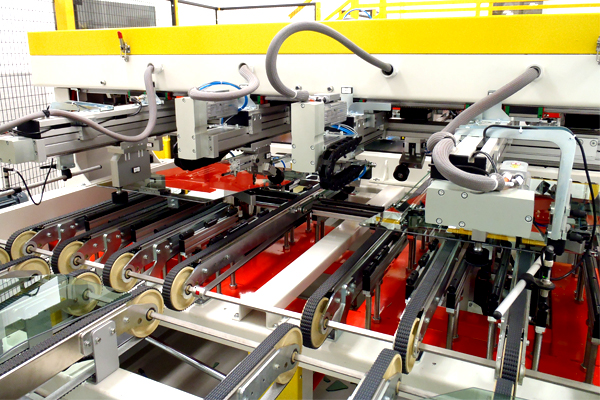

| Printing machines | 2x G130x200L Double Lites Edition with pre-alignment, corner conveyors |

| Dryers | 2 x infrared Dryer 2000 4 Hot Modules + 4 Cold Modules + Chiller Unit |

| Special equipment | Automatic Screen Alignment System, Broken Screen Detection Units, illuminated flat Inspection Conveyors, Vertical Stackers 60 Position, logo print unit, Automatic ink supply system, Part Tracking System, Line Supervisor System, Safety Access control system. |

| Total positions | 56 |

| Customer requirements | This outstanding printing line was engineered to satisfy the extremely high production needs of the customer. The line had to be able to print logos on 4 sidelites each 8 seconds and 4 sidelites (full print) or 2 backlites every 12 seconds with a productivity of 1200 sidelites/h or 600 backlites/h. The line offered great flexibility, since it was designed to be able to carry out double print process (black + silver) when used for Backlites. |

Supply description

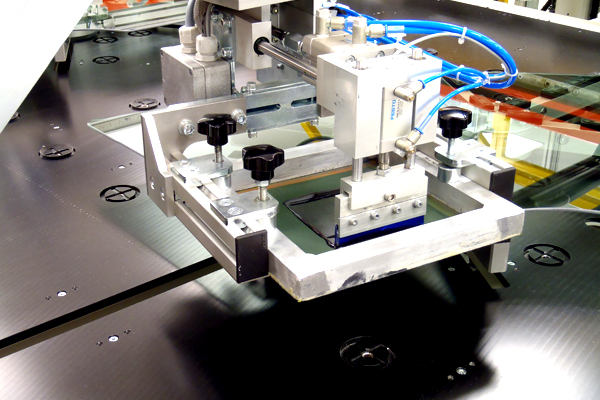

The special Silk Screen printing machine Series G 130x200L DLE (Double Lites Edition) was able to center and print two small glasses simultaneously.

For this special project a new centering system equipped with 18 Axes was engineered . The system enabled the centering of wide range of glasses with irregular shapes. The line layout was created with the scope to optimize and rationalize the space. The outcome was a project of a line devoleped on two different operational height levels. Thanks to this solution it was possible to use a single printing room, which reduced considerably the line lenght and the overall cost.