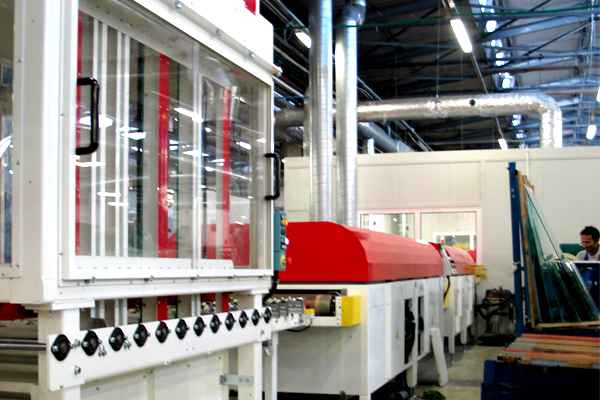

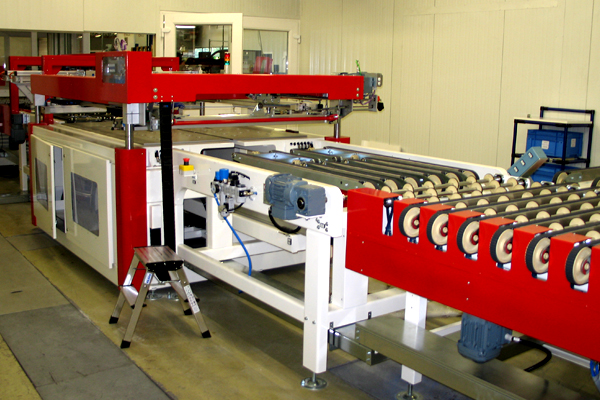

Double colour sidelites line

| YEAR | 2010 |

| Printing machines | 2x Series G 100x130S |

| Dryers | IR 130 2 hot modules + 2 cold modules+Chiller Unit Special equipment: Automatic Asymmetrical Centering System, Loading & Unloading Tilting tables, Part Tracking System. |

| Special equipment | Automatic Asymmetrical Centering System, Loading & Unloading Tilting tables, Part Tracking System. |

| Total positions | 10 |

| Customer requirements | Our customer invested in the installation of a new printing line for the production of Sidelites using two colors (black border and silver heaters). Since short batches were becoming a standard in the sector, it was crucial for Cugher to guarantee quick changeover. The glass shapes used in new car models were becoming more particular and challenging for the production process. For our customer it was very important to have printing lines able to process glass of any shape. |

Supply description

The customized line was composed by two printing machines Series G 100x130S. The first one was used for printing of the black enamel band around the periphery of the glass while the second one was used to print the heaters or the antennas with silver paste.

The sophisticated Line Automation Software was designed with the purpose to manage either the whole line or each machine individually when double printing process would not be required. This characteristic makes possible the to produce different glass models on each machine.

Both printing machines were equipped with the Automatic Asymmetrical Centering System which was capable of centering even glasses with very irregular shapes. To accomplish all customer’s requirement, the machines work with PLC with recipe system. The setup of the printers is fully automated therefore the changeover is very fast.