Printing line with UV Dryer

| YEAR | 2009 |

| Printing machines | Series G 130x200L |

| Dryers | UV Dryer 200 |

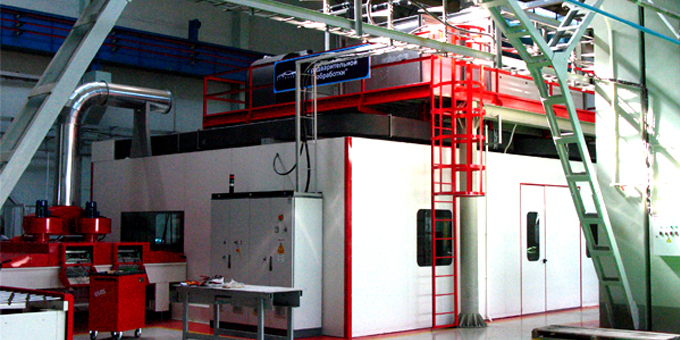

| Special equipment | Powdering machine, Glass Overlapping station, Unloading tilting table, Printing Clean Room, Part tracking System |

| Total positions | 26 |

| Customer requirements | The customer was an OEM automotive glass manufacturer. Their portfolio also includes glass for trucks, tractors and trains. They requested a fully automatic printing line for Windshields. It was mandatory that the line should operate with very high precision, due to the difficulties to find skilled workers in the region. It was essential that Cugher could guarantee the possibility to control every single parameter of the printing process, reducing to the minimum the risk of operator faults. |

Supply description

The line was capable to print automotive glasses and to handle bus glasses trough the powdering machine.

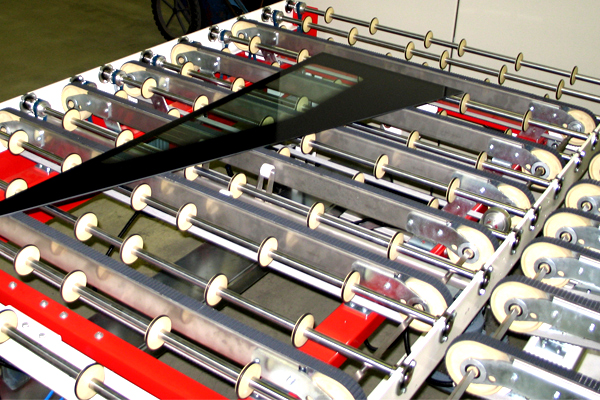

The fully optional Series G printing machine combined with part tracking software feature enabled simple line management. The interface was developed with the care to be user friendly and accessible even for operators with little experience.

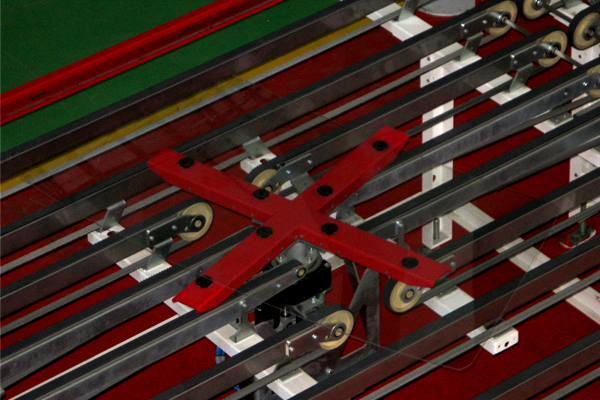

The glass overlapping process was completely automated with handling solution engineered by Cugher, thus the risk of contamination by manual handling was eliminated.

Effective energy economy was achieved by the use of UV Dryer 200. This type of dryer uses only 25%-30% of the energy consumed by equivalent IR dryer, maintenance cost are lower and there is significant optimization of the footprint.

The high quality of the produced glasses granted to the customer to meet the acceptance parameters of Daewoo, Chrysler & Toyota.

The flexibility of the line allows the processing of glasses with a very complex shape (typical characteristics of the glasses used for tractor, trucks & trains appliances)