Nowadays the production of flat glass products is extremely customized. A company is likely to have a complex production system designed to follow specific needs which take into consideration factors such as productivity, batch variety, dimension, shape and thickness of glasses. In every plant the ability to vary the process is therefore essential, with machinery not only perfectly synchronized, but also versatile and easily configurable. This becomes a greater challenge when the plant contains machines from different suppliers, which must all interface with each other to obtain a coordinated and high-performance production flow.

To mitigate this complexity Cugher offers its experience in designing machinery for glass handling with the aim of creating perfectly integrated systems for optimized loading of large processing machines.

Tempering, bending, coating are some of the processes that require the use of big machinery able to process more glasses at the same time. To take full advantage of these systems, loading must be optimized, perfectly synchronized with the downstream production cycle, which may change from one batch to another. Aware of these needs, Cugher creates and produces highly dynamic and flexible customized solutions for loading to ensure maximum efficiency. Each solution come comes from a careful study of a customer’s requirements and from a continuous dialogue, resulting in the consultative approach that characterizes the Cugher method.

Among production requirements processed by Cugher there is, for instance, the need to automatically modify loading according to the length of the array and in relation to the line speed, with the aim to obtain the maximum performance, a higher control on costs and minimizing machinery wear.

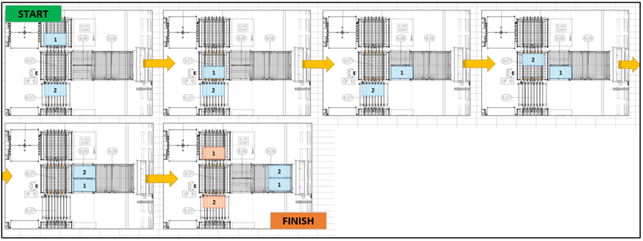

Let’s take as our example the need to place side by side two glasses coming from two different parts of the line, to create a pair of glasses travelling together towards the next process. Cugher has designed a special system of conveyors that allow different configurations. The first one places long-edge-leading glasses one next to the other, changing the loading orientation on short-edge and allowing them to enter simultaneously.

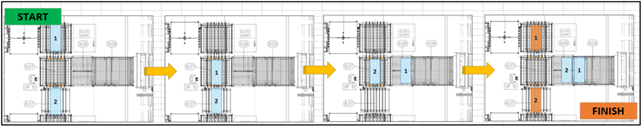

The second configuration facilitates the arrangement of short-edge-leading glasses in sequence, to be loaded on their long-edge, one after the other.

To realize arrays of four glasses, these mechanisms are repeated twice, assuming that the dimensions of glasses allow this in proportion to that of conveyors. Obviously, these systems also permit loading of a single glass, if the production requires this.

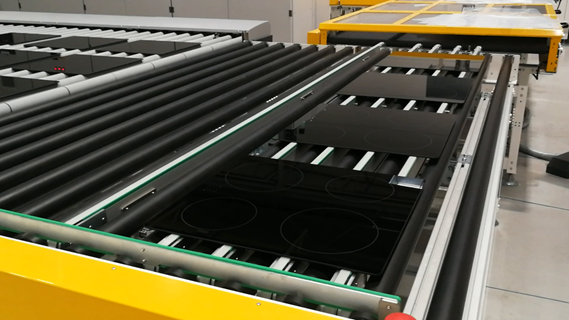

Systems such as the one just described are the result of particular settings on more classical conveyors, rollers or belts, always produced by Cugher, and that use a minimum contact surface and guarantee the maximum grip. For instance, to meet the requirement of a variable height conveyor for loading, Cugher combines the technology of a roller conveyor with the one of a lift.

The development of software is also essential in every loading system to satisfy all different required functionalities, with the purpose of having precise and synchronized movements.

The choice of different programmed configurations is facilitated through the Cugher operator panel, which enables easy and immediate control on all machinery.

Cugher has made machine customization a differentiating factor over the years. Request for ever-increasing performance and personalized loading systems are met by the company’s technical department to develop optimal solutions for each customer.