Having earned the trust of some of the industry’s greatest titans, CUGHER’s plant both designs and produces advanced screen printing machines for automotive glass decoration. While its J Series automates printing for medium to large glasses, its flexible G Series handles asymmetrical glasses. A global industry player, Cugher now numbers AGP, Sisecam, Saint Gobain and AGC among its customers.

More traction for production

Having invested in the Cugher’s capability to provide big and technological plants for screen printing, its customers can now see the result of their trust in the company’s 7.600 m² production plant. Today Cugher is able to design and produce a wide range of products for processing flat glass, from consolidated silk screen printing machines to dryers and handling systems – all perfectly synchronized and automated to ensure high productivity and the typical quality standards of the automotive sector. For vehicle glass manufacture, complex plants necessitate the capacity to reach high volumes of final products with a minimum percentage of bad glass and maximized desired quality. As for glass decoration, screen printing currently performs the best and is the most profitable solution for the automotive industry. Perfecting this technique, Cugher has strengthened over the years as a brand.

Crafting quality

Cugher printing machines guarantee a +/- 0.08 mm repeatability, ink uniformity, very short cycle time (from six to 15 seconds) and extremely easy maintenance. The engineering of each machine is meticulous in every detail to ensure precise results with all parameters perfectly set. All printing machines are equipped with digital proportional valves, anti-drop system, printing bridge rotation, automatic peel off, motorization for frame movements and pneumatic block of squeegee, flood bar and frame to avoid losing the register. Furthermore, each machine can be integrated with other sophisticated accessories to simplify operations – such as the edge-to-edge system for edge printing, the logo printing head, system unity to troubleshoot corner breakage and an automatic ink distributor.

Reliable know-how

The expertise of Cugher professionals will suggest the ideal line solution to accommodate the specifications of single production requirements – all the while considering plant space availability, productivity, glass material, shape and dimension. Every project is perfectly customized such that the final layout is the result of a continuous dialogue to ensure satisfaction respecting every need. Cugher has developed veritable workhorses of screen printing for the automotive industry, namely the J and G series respectively.

The J Series

A completely automated printing machine that can process glass to medium and large dimensions, i.e. up to 2500×4000 mm. The glass arrives via inlet conveyor through motorized belts, which lower directly in the printing table where the glass is centered thanks to adjustable pins. When the printing process ends, the transportation system lifts to transfer the glass onto the exit conveyor.

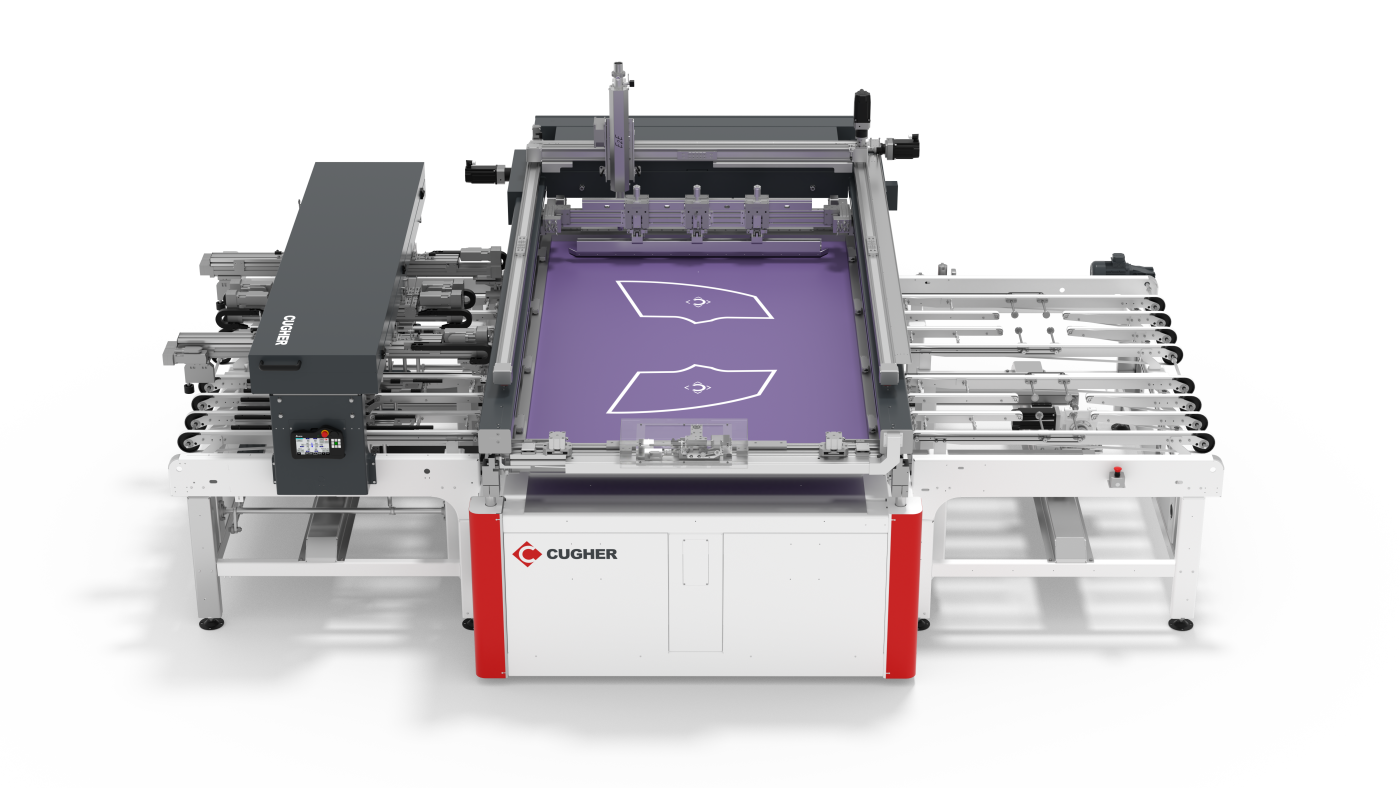

The G Series

Being more suitable for asymmetrical glasses, the G Series is extremely flexible given that it can process either single big glasses (windshields or backlites) or double smaller glasses (sidelites) – always ensuring fast cycle time. Here speed performance is obtained through shuttle transportation equipped with two independent supports that include vacuum cups which collect the glass in the inlet conveyor, whereupon it gets centered by a multi-axial system. The glass is then transferred very swiftly and with accuracy onto the printing table for decorating.

Celebrating growth

For Cugher, the J and G series have made history in the automotive sector – satisfying the projects of such big multinationals as AGP, Sisecam, Saint Gobain and AGC. The company has seen significant growth thanks to its development of screen printing lines for automotive – making it a robust partner globally for both personalized and complex solutions.