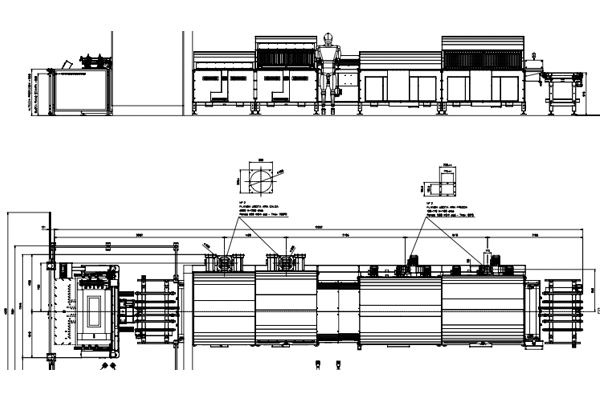

Semi automatic printing line

| YEAR | 2012 |

| Printing machines | LS 50x100 |

| Dryers | IR 1000 2 hot modules + 2 cold modules |

| Special equipment | rear outlet conveyor and unloading conveyor |

| Total positions | 4 |

| Customer requirements | The customer manufactures glasses for offroad vehicles and boats. They needed to extend the current production capacity. The typical production is small to medium glass batches with wide range of shapes. This was the reason why the main priority was to ensure rapid model change system with no impact on the printing quality. This requirement was met by choosing a very flexible solution, a based on a semi-automatic LS Series machine, with a 2+2 IR modules. |

Supply description

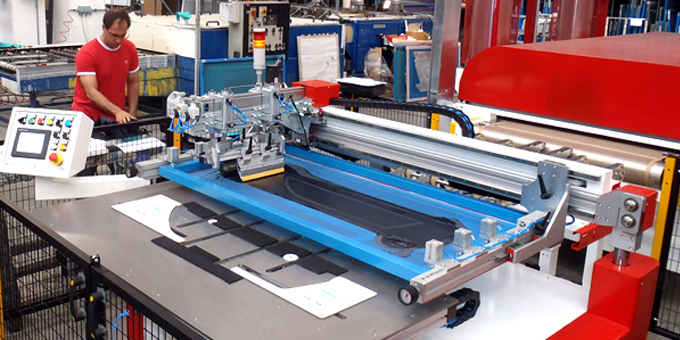

The line was composed by the Series LS printing machine and an IR dryer. The LS is a Semi Automatic machine which can be used for glasses having dimension up to 1000 x700 mm. Based on the specific process and the skilfulness of the operator, the machine could print to 300 pcs/hour. The set up time of the Series LS machine was very short and controls were accessible and easy to manage. This characteristics defined it as the perfect solution for medium and small batches that require a quick change over. The IR dryer was designed to match the machine productivity level.