Besides jointly offering machinery for electrical circuit screen printing with its reliable partner Acelabs, which designs and produces quality control solutions, Cugher ensures track precision while conducting completeness checks.

Electrical circuit printing finds significant application within the glass sector – particularly for automotive. Here the most common applications include thermal backlite tracks for glass defrosting, antennas in windshields, camera defrosts and wiper heaters mainly used in countries with cold weather.

Cugher’s vision system is installed at the center of the precision roller conveyor after the printing phase – just where space affords sufficient movement for the camera and illuminator to proceed to inspection of the printed circuit without compromising conveyor movement and hence halting production.

Image resolution

Here the 16384-pixel monochromatic camera is standard use (though for very thin tracks, a 32768-pixel camera may be preferred), thus guaranteeing a resolution of:

- up to 60µm (0.06 mm/pixel) for the 1000 mm glasses;

- up to 80µm (0.08 mm/pixel) for the 1300 mm glasses;

- up to 122 µm (0.122 mm/pixel) for the 2000 mm glass

The linear camera acquires one line at a time by “scanning” the glass during its movement along the conveyor – all with the track illuminated by a light at a specific wavelength.

Defect detection

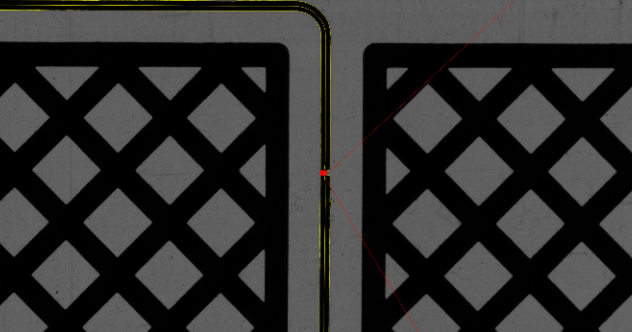

With a view to identifying different defects, quality control is designed to automatically check every detail of the silver tracks printed upon the glass: ink leaks, missing ink along the track, track width variations, indentation edges along the track, off-track impurities, as well as islands and small ink craters. It’s possible when executing an automatic optical control to verify circuit continuity, thinning of the track (which can result in a “hot spot”) and any short circuits – all of which, as check and test types, are denominated “non-destructive”.

For different glass areas, and starting from a digital or real image that’s “good”, inspection sensitivity can be set by the operator to different possible sensitivities given the need for a single image during inspection.

Analysis and corrective actions

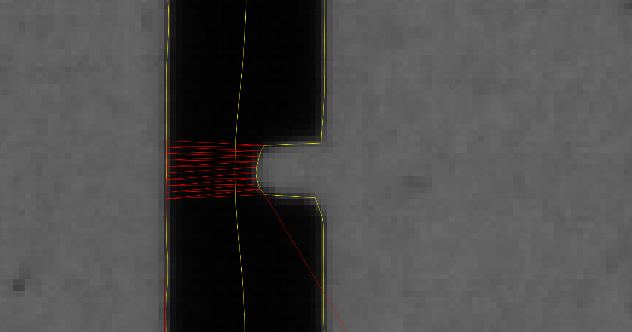

Acquired images are displayed on a high-resolution monitor so the operator, where necessary, can zoom over selected areas to analyze image details with more precision. Here the software will highlight any defects in red after automatically tabulating detected errors.

Also, the system can automatically perform functions retroactive to the printing machine, such as modifying screen position in real time or another corrective action necessitated after some circumstance set during programming has been identified.

Ensuring high product standards

Vision systems allow for the elaboration of particulars invisible to the human eye by way of optical instruments and specific software – thereby achieving a product quality that’s ever more compliant with market needs.

In sum, the application of Cugher vision systems guarantee:

- Checking of the entire production

- High control speed

- Customization and regularity of evaluation criteria

- Evidence of variances on optimal parameters

- Quick corrective actions

- Reduction of error-based costs